Tiny House

Materials:

Frames and trusses are made in Australian-made Truecore steel coils (*)

All Pods Include:

-

Frames and trusses are designed by default for N2 wind region conditions. Any requirement for higher wind classification (e.g., N3, C1) will incur additional design and supply charges.

-

Design and structural certification by a qualified engineer

-

Prefabricated wall panels for external, internal, and parapet walls (if applicable)

-

Roof trusses or roof panels as per installation drawings

-

K-braces and webbed lintels over openings (per engineering design)

-

Spare studs (C89x41) for strong-back supports between roof trusses

-

Installation layout drawings and typical connection details

T004

A wonderful design offers a splendid view from the bedroom on the upper deck level. the ground floor combines living, meal space and kitchenette, and spacious bathroom.

The subfloor structure is open for LGS panels or a combination of structural steel that depend on whether the building is built on-site or off-site. Open for the discussion for the most optimal way to build.

T002

A quote but spacious space for working from home, attached to the workshop! The subfloor structure is open for LGS panels or a combination of structural steel that depend on whether the building is built on-site or off-site. Open for the discussion for the most optimal way to build.

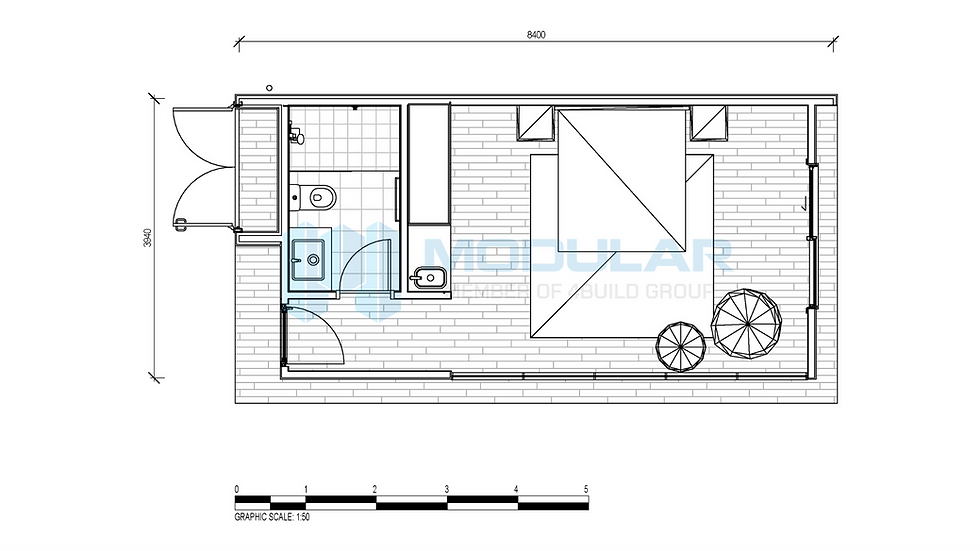

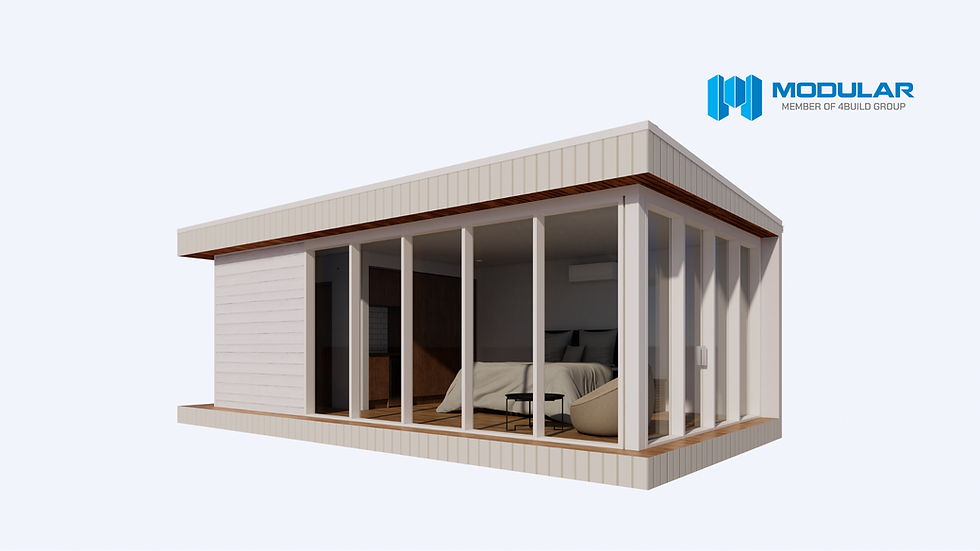

T003

This pack can be for various options of design such as a shop/ home office/ studio or one bedroom suite.The subfloor structure (base) is built from floor panels on one-way bearers spanning the footing stumps. This design is suitable to be built on-site.

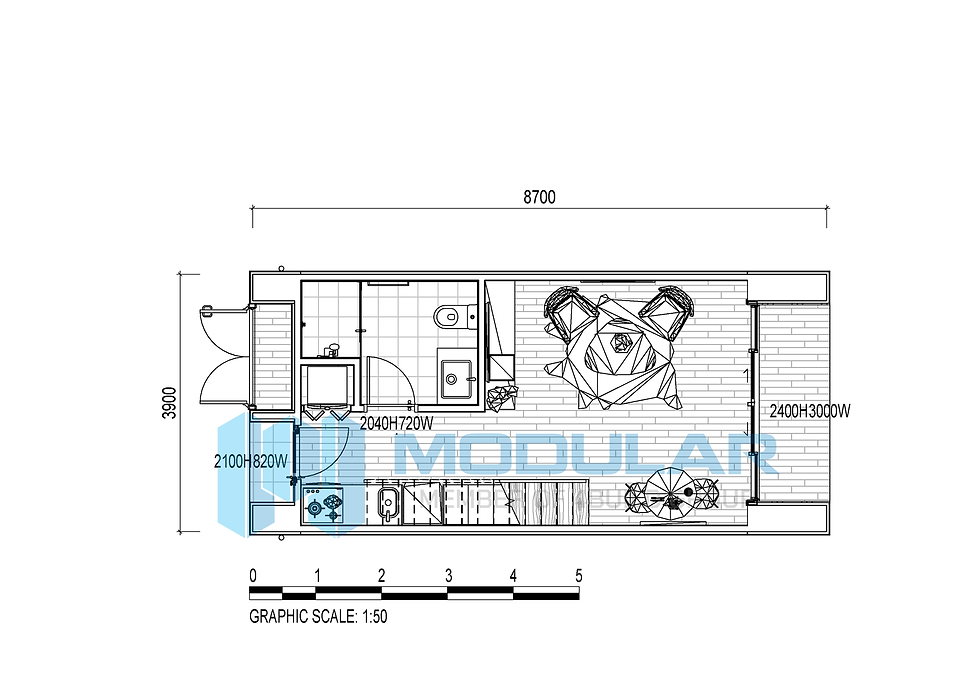

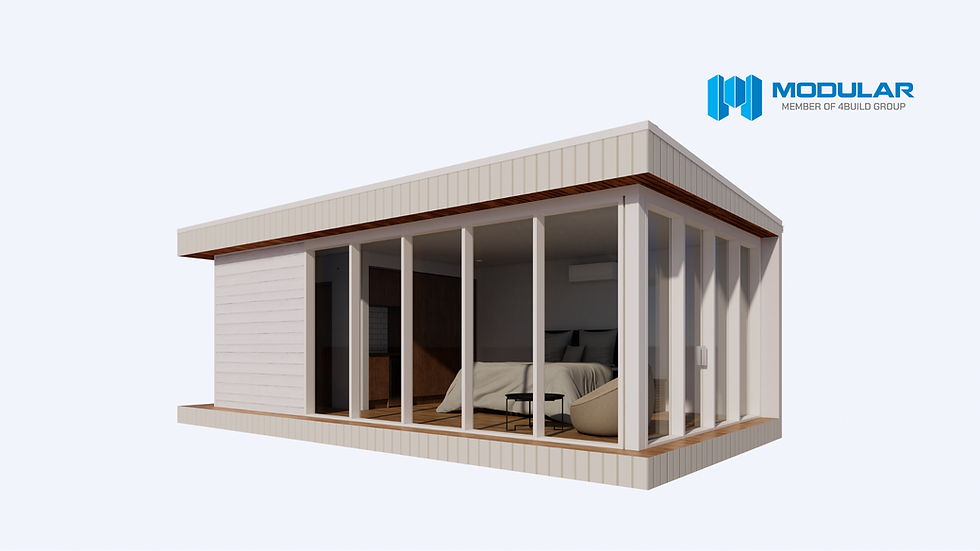

T001

Perfect space with a King size bed that looks out to the great view in the garden.

The bathroom with shower cabin, and wardrobe next to the bar are all arranged inside the house.

The subfloor structure is open for LGS panels or a combination of structural steel that depend on whether the building is built on-site or off-site. Open for the discussion for the most optimal way to build.

How It Works

Phase 1

Quoting

At M-Modular, we meet the unique requirements of our clients with remarkable precision, ensuring a competitive price in the Australian market. Our bespoke approach guarantees maximum value and satisfaction for every project we undertake.

Phase 3

Manufacturing

M-Modular utilizes cutting-edge FRAMECAD® technology to manufacture premium light gauge steel frames for modular housing. Our state-of-the-art production facilities enable us to produce high-quality components with unrivaled efficiency, ensuring swift project completion and cost savings for our clients.

Phase 2

Engineering

Our expert engineering team is dedicated to ensuring that every frame we produce meets the strictest Australian building codes. Through advanced structural analysis and precise truss calculations, we guarantee that each frame is not only robust but also optimized for efficiency and longevity. With a focus on both performance and sustainability, our engineers ensure your project is set for success from the ground up.

Phase 4

Installation

We are dedicated to assembling our top-quality frames on-site in a timely manner, strictly adhering to Australian construction standards and timelines. Our skilled installation team works seamlessly with other trades, ensuring a smooth and coordinated building process that minimizes delays and maximizes client satisfaction.